The ceramics industry has reached a significant milestone with the successful development of zirconia-based ceramic inserts boasting a sintered density of 8.0 g/cm³. This achievement marks a substantial leap forward in material performance, particularly for applications requiring extreme wear resistance and structural integrity. Unlike conventional ceramic components that typically exhibit lower densities, this advancement opens new possibilities for high-stress industrial applications where material failure is not an option.

Material scientists have long recognized zirconia's potential, but achieving such high density levels required overcoming substantial technical challenges. The key lies in optimizing the sintering process - the high-temperature treatment that transforms powdered zirconia into a solid, dense structure. By carefully controlling temperature profiles, pressure conditions, and nano-scale particle distribution, researchers have created a material with near-theoretical density. This eliminates nearly all porosity that could compromise mechanical strength or chemical stability.

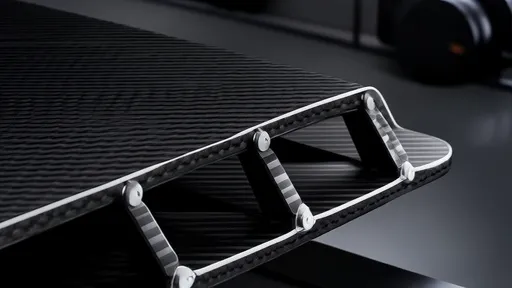

Industrial applications for these ultra-dense zirconia inserts are numerous and transformative. In the medical field, dental implants and prosthetic joints benefit from the material's combination of high strength and biocompatibility. The aerospace sector values these components for turbine blades and heat shields where both light weight and thermal resistance are critical. Perhaps most significantly, manufacturing industries are adopting these inserts for cutting tools that outperform traditional carbide alternatives, particularly when machining superalloys or abrasive composites.

The manufacturing implications of this density achievement are profound. Components produced at 8.0 g/cm³ demonstrate approximately 15-20% greater fracture toughness compared to standard-grade zirconia ceramics. This translates directly to longer service life and reduced downtime in industrial settings. Furthermore, the material's enhanced thermal conductivity - a direct result of minimized porosity - allows for better heat dissipation in high-temperature applications. These characteristics make the new zirconia formulation particularly valuable for applications involving thermal cycling or rapid temperature fluctuations.

Quality control represents another area where this advancement makes an impact. The consistent achievement of 8.0 g/cm³ density indicates exceptional process control throughout production. Manufacturers report that components now exhibit dimensional tolerances within ±0.1% of design specifications, a level of precision previously unattainable with ceramic materials. This reliability opens doors to applications where ceramic components must interface precisely with metal assemblies without compromising the integrity of either material.

From a commercial perspective, the availability of zirconia inserts at this density level is reshaping supply chains across multiple industries. While the production costs remain higher than for conventional ceramics, the total cost of ownership often proves lower due to extended component lifespan and reduced maintenance requirements. Early adopters in the automotive sector report that forming tools equipped with these inserts maintain cutting edges up to three times longer than previous generations, significantly improving production efficiency.

Looking ahead, researchers are exploring ways to further enhance zirconia's properties while maintaining this exceptional density. Current investigations focus on dopant materials that could improve electrical conductivity for specialized applications, as well as surface treatments to optimize friction characteristics. As these developments progress, zirconia ceramics with 8.0 g/cm³ density may become the new standard for high-performance industrial components, potentially displacing traditional materials in applications where only metals previously could perform.

The successful production of zirconia ceramic inserts at 8.0 g/cm³ represents more than just a materials science achievement - it signifies a shift in how engineers approach component design for extreme environments. By combining ceramic advantages like corrosion resistance and high-temperature stability with mechanical properties approaching those of some metals, this development blurs traditional material boundaries. As manufacturing processes scale and costs potentially decrease, we may witness a quiet revolution in industrial materials selection, with ultra-dense zirconia playing a leading role.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025