The aerospace industry has always been at the forefront of material innovation, constantly pushing boundaries to achieve better performance through advanced engineering solutions. Among these innovations, carbon fiber reinforced polymers (CFRP) have emerged as game-changers, particularly in structural components where weight savings directly translate to improved efficiency and reduced operational costs.

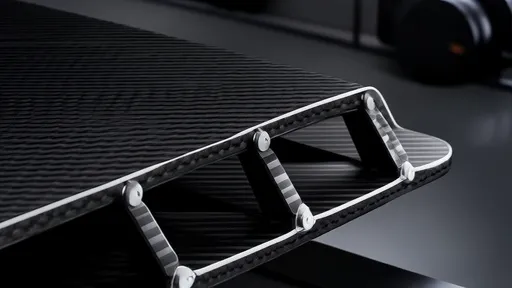

One of the most significant applications of carbon fiber in aviation has been the development of aircraft brackets that achieve remarkable weight reductions without compromising structural integrity. Recent advancements have demonstrated that properly engineered CFRP brackets can reduce weight by up to 40% compared to traditional aluminum counterparts while maintaining equivalent or superior load-bearing capabilities.

The shift from metal to composite brackets represents more than just a simple material substitution. Aircraft brackets, often considered "secondary structures," play crucial roles in supporting various systems throughout an aircraft's airframe. These components must withstand substantial static and dynamic loads while resisting vibration, fatigue, and environmental factors. The successful implementation of carbon fiber in these applications required rethinking traditional design approaches to leverage the material's anisotropic properties.

Traditional aluminum brackets are typically machined from solid blocks of material, resulting in components that often contain more material than structurally necessary. Carbon fiber composites allow for optimized designs where fibers follow stress paths precisely, eliminating unnecessary material while reinforcing areas under high stress. This topology optimization, combined with carbon fiber's inherent strength-to-weight advantage, creates the perfect conditions for dramatic weight reduction.

Manufacturing techniques for aerospace-grade brackets have evolved significantly to meet the stringent requirements of flight-critical components. Automated fiber placement (AFP) and advanced compression molding processes enable the production of complex, near-net-shape brackets with precisely oriented fiber layups. These methods allow engineers to tailor stiffness and strength characteristics in different directions within a single component, something impossible with isotropic metals.

The transition to carbon fiber brackets hasn't been without challenges. Early attempts faced issues with impact resistance and damage tolerance—critical factors in aerospace applications. Modern CFRP formulations now incorporate toughened resin systems and hybrid fiber architectures that provide excellent damage resistance while maintaining the desired weight savings. Additionally, advanced non-destructive testing (NDT) methods ensure these components meet rigorous quality standards before entering service.

Performance benefits extend beyond simple weight reduction. Carbon fiber brackets demonstrate superior fatigue resistance compared to metal versions, particularly important for components subjected to constant vibration during flight. The material's corrosion resistance eliminates concerns about degradation from moisture, chemicals, or temperature fluctuations. Furthermore, CFRP's vibration damping characteristics can improve overall system reliability by reducing stress on connected components.

The environmental impact of lighter aircraft components shouldn't be overlooked. A 40% reduction in bracket weight contributes to lower fuel consumption across an aircraft's service life. When multiplied across hundreds of brackets in a single aircraft and thousands of aircraft in global fleets, the cumulative effect on emissions reduction becomes substantial. This aligns perfectly with the aviation industry's commitment to sustainable operations and reduced carbon footprints.

Implementation in next-generation aircraft programs has accelerated as major manufacturers validate the technology. Both Boeing and Airbus have incorporated carbon fiber brackets in their latest models, with suppliers developing specialized expertise in high-performance composite components. The military aerospace sector has been particularly aggressive in adoption, where performance gains often justify higher initial costs.

Supply chain considerations have played a significant role in the technology's maturation. Traditional metal bracket suppliers have invested heavily in composite capabilities, while new specialists have emerged focusing exclusively on advanced composite components. This ecosystem development ensures reliable production capacity and continuous innovation in manufacturing techniques and material formulations.

The economic case for carbon fiber brackets strengthens as production volumes increase. While CFRP components traditionally carried a significant cost premium, improved manufacturing efficiency and material utilization have narrowed the gap. When considering total lifecycle costs—including fuel savings, reduced maintenance, and longer service intervals—the value proposition becomes compelling for operators.

Future developments promise even greater advancements in aerospace bracket technology. Researchers are exploring nanomaterial-enhanced resins for improved performance characteristics, while digital twin technology enables more aggressive optimization of component designs. Additive manufacturing approaches for carbon fiber components may soon provide additional flexibility in bracket geometries and further weight reduction opportunities.

Certification remains a careful, methodical process for flight-critical components. Regulatory bodies like the FAA and EASA have developed comprehensive standards for composite aircraft structures, with bracket applications benefiting from this established framework. The successful track record of early adopters has paved the way for broader acceptance across the industry.

As the technology matures, retrofitting existing aircraft with carbon fiber brackets has emerged as a viable option for operators seeking performance improvements without purchasing new airframes. MRO (Maintenance, Repair, and Overhaul) providers now offer composite bracket replacement programs that can reduce weight on in-service aircraft during scheduled maintenance events.

The human factor in this technological transition shouldn't be underestimated. Widespread adoption required training programs for engineers, technicians, and inspectors to develop competency with composite materials. Universities and technical schools have updated curricula to prepare the next generation of aerospace professionals with composite-specific knowledge and skills.

Looking ahead, the success of carbon fiber brackets in aerospace applications serves as a model for other industries seeking weight reduction solutions. The lessons learned in material science, manufacturing processes, and qualification testing provide valuable insights that can accelerate adoption in automotive, marine, and industrial applications where lightweighting provides similar benefits.

The 40% weight reduction achieved with carbon fiber brackets represents more than just a technical milestone—it demonstrates how material innovation can drive systemic improvements across entire industries. As aerospace continues to push the boundaries of what's possible with advanced composites, these humble but critical components will play an increasingly important role in shaping the future of flight.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025